APPLICATION

APPLICATION

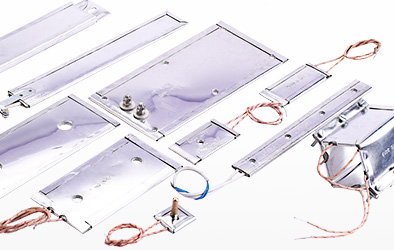

HS / FS Ring Elements owing to their convenient shape & sizes, adapt themselves readily to variety of machines and appli-ances for which other type of heaters are not suitable. They are being fitted for heating platens, dies of presses. They are also in use for melting of glue, wax, easily fusible metals like leads, tin, solder, hot plates, valves, flanges, brooders, vulcaniz-ers, popcorn machines, high speed packing machines, diffusion pumps, tank bottoms, kettles, large coffee percolators & wash boilers etc.

CONSTRUCTION

CONSTRUCTION

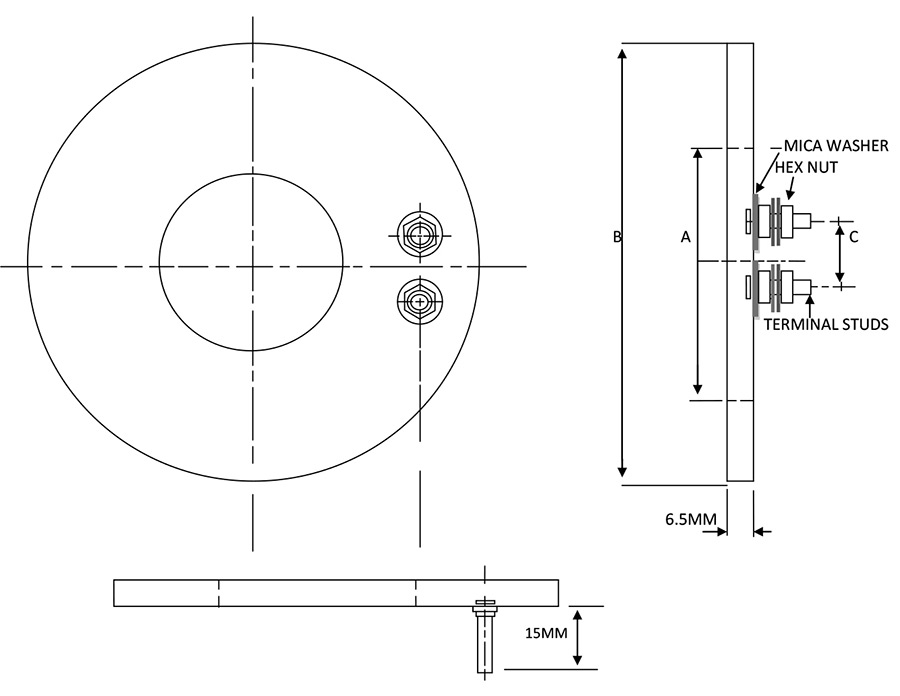

Chrome steel sheath on one side and edges, other flat side is the bare refractory. Coiled electric resistant wire embedded inside. And steel terminal studs with nuts and washers.

FEATURES

FEATURES

Being sheathed on one side only, it has very little residual heat and stands up to 650°C temperature for its surface area. Elimination of the sheath on the contact side puts the rock hard refractory in direct contact with the heated surface, thereby providing slightly faster heat-up. Half Sheath elements can be used where the protection provided by the full sheath is unnecessary.

Fully Sheathed Heaters (both sides metal) provides extra protection from rough handling & usage, especially when there are chances of falling any liquid on it.

INSTALLATION & PRECAUTIONS

INSTALLATION & PRECAUTIONS

- Always use the largest possible numbers of heaters in order to reduce the density in Watt for sq.cm.

- Ensure the base of the surface is flat to ensure maximum thermal contact with the heating elements.

- The Heaters shall be so installed so that the Ratings are easily visible when required to be replaced in case of faults or for checking after installation.

- The installation shall be such that Mains parts are not be exposed, easily accessible and touched by finger.

- Install heat insulation to avoid excess heat loss but do not back directly against the element.

- Use heat resisting wires for electrical connections. Protect lead exit from contaminations by electrically conductive substances, mechanical shock, excessive flexing, excessive temperature & moisture.

- Use crimped lugs of appropriate size and construct it so that no strands are loose. Shall be tightened with appropriate torque so that there is no loose connection.

CLAMPINGS

CLAMPINGS

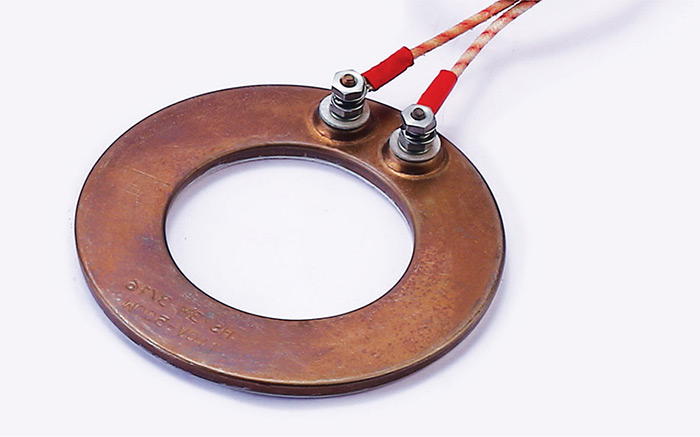

Cast-iron clamps, for ring elements, retain their strength at elevated temperatures to assure maximum sheath-to-surface contact. Resulting uniform efficient heat transfer from internal resistance wire to the heated material minimize hot spots on the element, contributing to long service life.

METHODS OF MOUNTING HS / FS RING HEATERS

METHODS OF MOUNTING HS / FS RING HEATERS

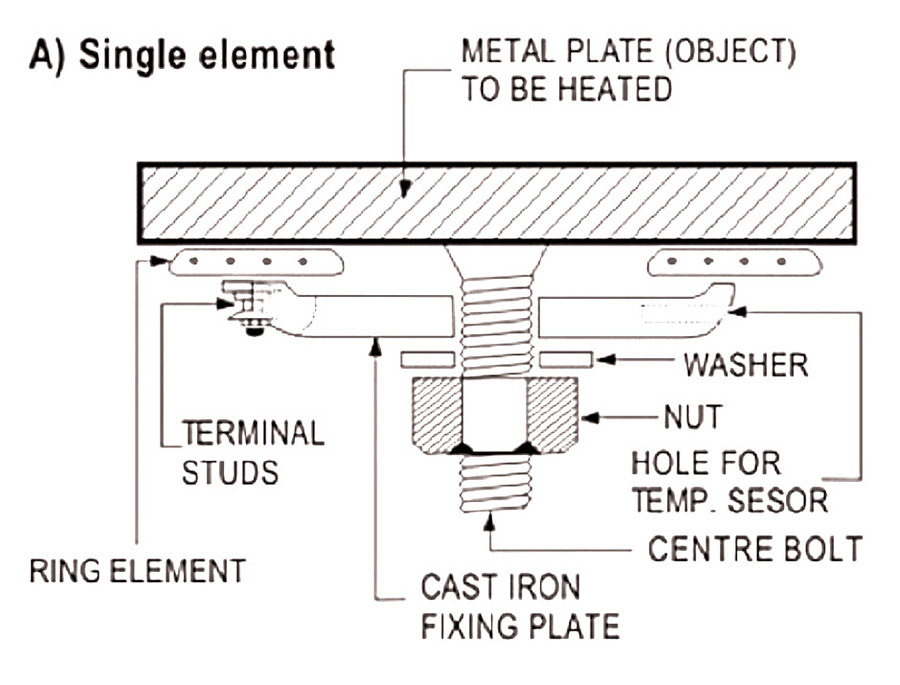

If the utensil is having thick bottom. The mounting of the element is very simple. A centre bolt & a concave fixing plate alone being necessary, as shown.

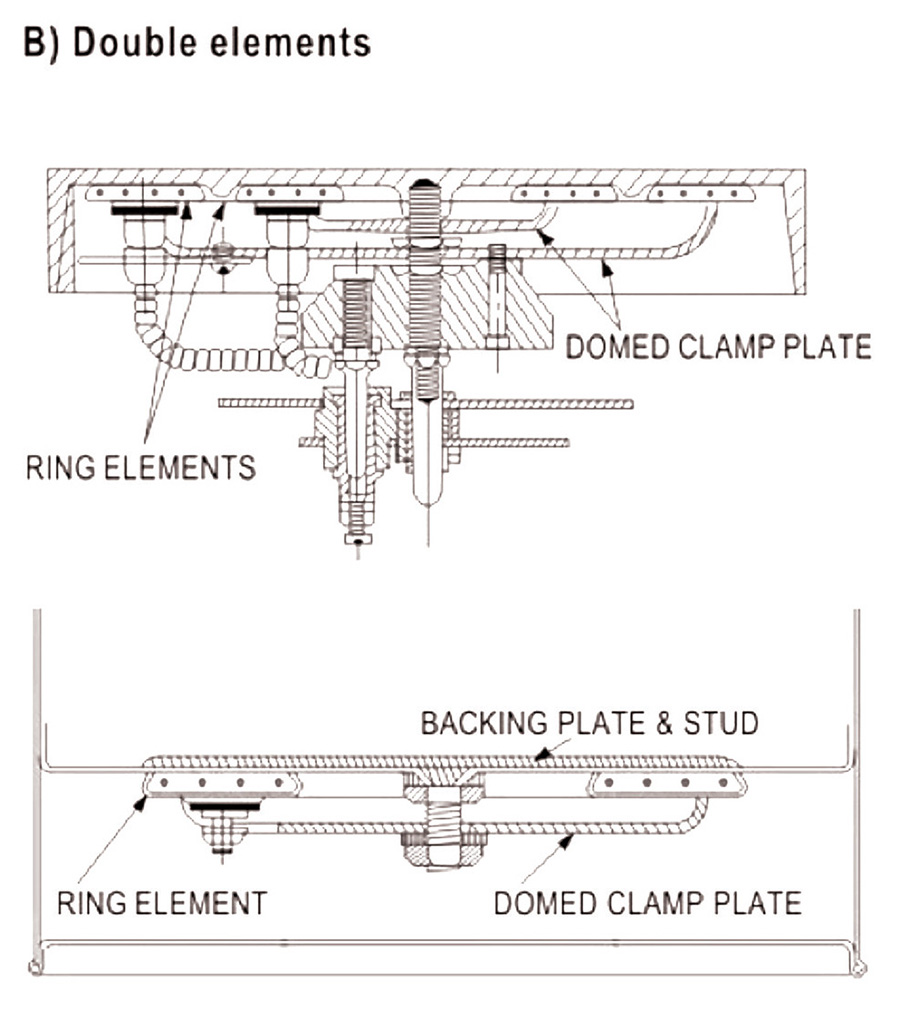

If the utensil button is thin, we suggest to strength it by means of brass / SS backing plates which makes one piece with the fixing bolt mounted as shown.

STANDARD SIZES

STANDARD SIZES

| Types | Max. Watts @230 Valts |

Half Sheated (Type HS) |

Full Sheated (Type FS) |

||

| ID (mm) |

OD (mm) |

ID (mm) |

OD (mm) |

||

| HS-1/FS-1 | 350 | 27 | 87 | 25 | 89 |

| HS-2/FS-2 | 400 | 50 | 100 | 48 | 102 |

| HS-3/FS-3 | 500 | 50 | 111 | 48 | 112 |

| HS-4/FS-4 | 1000 | 62 | 134 | 60 | 136 |

| HS-6/FS-6 | 1250 | 90 | 160 | 88 | 161 |

| HS-7/FS-7 | 1300 | 113 | 178 | 111 | 180 |

| HS-8/FS-8 | 1600 | 129 | 201 | 126 | 203 |

| HS-9/FS-9 | 1750 | 152 | 218 | 151 | 220 |

| HS-10/FS-10 | 2000 | 225 | 300 | 223 | 302 |

- HS-1 have 4BA thread terminal studs and all others types have 2 BA thread studs.

- Tolerance in dimension +/- 0.5mm

- Heater is not recommended for direct immersion in liquid.

- Heater with different Wattage & Voltage can also be made on acceptable quantity and at special price.

- Dimensions are subject to change without notice.

- Available in E.P.S., E.P.E. packing contains two & ten pieces.

These Heaters can be used one inside the other in the following manners.

- FS-10 + FS 9 + FS 4 Total Power 4750 Watts.

- FS-9 + FS 4 Total Power 2950 Watts.

- FS-8 + FS 3 Total Power 2100 Watts.

- FS-7 + FS 2 Total Power 1700 Watts.

TERMINALS SPECIFICATIONS

TERMINALS SPECIFICATIONS

| Types | MAX WATTS AT 230/250 VOLTS |

DIEMENSION (IN MM) A |

DIEMENSION (IN MM) B |

CENTRE DISTANCE (IN MM) C |

TERMINAL STUDS THREAD SIZE |

| HS-1 | 350 | 27 | 88 | 16 | 4 BA |

| HS-2 | 400 | 50 | 100 | 21 | 4 BA |

| HS-3 | 500 | 50 | 111 | 21 | 4 BA |

| HS-4 | 1000 | 62 | 134 | 21 | 2 BA |

| HS-6 | 1250 | 90 | 160 | 21 | 2 BA |

| HS-7 | 1300 | 113 | 178 | 21 | 2 BA |

| HS-8 | 1600 | 129 | 201 | 21 | 2 BA |

| HS-9 | 1750 | 152 | 218 | 21 | 2 BA |

| HS-10 | 2000 | 225 | 300 | 21 | 2 BA |