HIGH DENSITY CARTRIDGE HEATERS

APPLICATION

APPLICATION

To Heat dies & moulds, Smelting of materials, heating of fluids & heat welding etc. HD cartridge heaters are able to with-stand the toughest working conditions such as vibration, moisture, fluids, spills, frequent expansions & where the temp. Is 400 to 750 Deg. C. are required, or temperatures within a limited space.

CONSTRUCTION

CONSTRUCTION

High-wattage cartridges belong to a new generation of electric heat-ing elements; they make it possible to use high watt loads in small spaces, thus ensuring excellent reliability in heavy-duty work condi-tions. Their special construction technology makes them the most advanced type of heating elements. The entire length of the wire wound around a magnesium oxide core is in a far away position from the axis of the cartridge, very close to the metal sheath, with a very thin and compressed insulating wall in between; this allows excellent heat exchange that allows a much lower temperature of the resis-tance wire than in other heaters in which the wire is in a deeper posi-tion. Besides the use of advanced technology and precise inspection techniques in their manufacturing.

INSTALLATION & PRECAUTIONS

INSTALLATION & PRECAUTIONS

- The hole where it is going to be isntalled, the cartridge must have a diameter tolerance between –0.02 to –0.06 mm (depends upon watt density, higher watt density must have lower tolerance).

- The cartridge must not be longer than the hole where it is installed.

- Connecting leads must not be scratched, flattened, stained, wet, etc.

- The cartridge heaters cannot work in open air.

- Controlling systems must be used with the cartridge heaters.

- Resistance Tolerance: + 10% - 5%

- Wattage Tolerance: + 5% - 10%

- Length Tolerance: +/- up to 5mm

- The sensors for the controller should be placed between the working surface of the part & the heaters. The temperature of the part approximately half inch away from the heaters is used in selecting maximum allowable watt density.

- Control of power is an important consideration in high watt density appl cations. On/Off control is frequently utilised, but it can cause wide excursions in the temperature of the heaters & working parts. Thyristor power control are valuable in extending the life of the high watt density heaters, since they effectively eliminate On/Off cycling.

MEDIUM WATT DENSITY CARTRIDGE HEATERS

Cartridge heaters are recommended wherever the performance of cartridges is not fully needed. In construction, the same materials used in are used, though manufacturing technology is simpler, due to lower watt density, and therefore the whole process is more economical.

Cartridges have one or more U-bent spirals in a cartridge core of compacted magnesium oxide, with the spirals nearer to the axis of the cartridge than in heaters, as heating power is lower and thermal conductivity of com-pacted magnesium oxide is highly sufficient to spread heat, therefore with total reliability and safety even in extreme work conditions. Due to their simple construction, cartridges are perfect for being shaped in various ways for the application needed. They can have cold sections at ends, and/or with differentiated watt densities or indepen-dent circuits for separate sections.

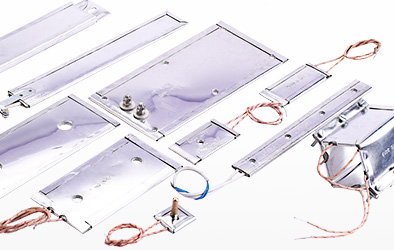

'D' TYPE CARTRIDGE HEATERS

FEATURES

FEATURES

Cartridge heaters are most frequently used for heating metal parts by insertion into drilled holes. The ‘D’ heater is designed especially for platen, die or mould commercial heating applications where the holes are poorly drilled or worn through age. Independent expansion of each section of the when energized, creates intimate contact with the wall of the hole.

- Split Sheath design

- Improved conductive heater

- Easily inserted and removed from long holes

- Incolloy Sheath for long life at extreme temperatures

- Compacted to maximum density for excellent element to sheath heat transfer and dielectric strength